Next-Gen Manufacturing For CNC Machining & Injection Molding

We are the most comprehensive and efficient manufacturer, tailored to meet your exact needs.

From prototyping to production, we ensure quality and precision at every stage of your project.

Volume pricing built to fit your budget

Expert program management throughout your project

Strict quality control processes at every stage

Flexible capabilities to meet design challenges

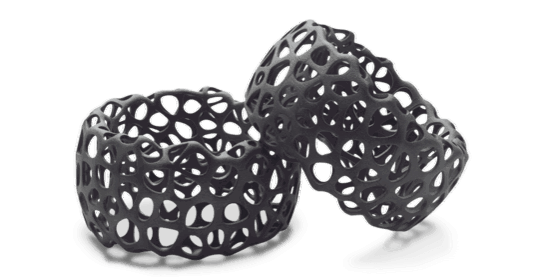

Quick-turn, affordable, high-quality molded parts for both prototyping and production. No MOQ required, with volume pricing available.

Our injection molds last 50% longer than other molds, They can run up to 15-20 years in most cases.

By Using CNC Milling and CNC Turning, We can make Your parts without geometry or material Limits.

What Our Customers Say

Trusted by Engineers and Purchasing Leaders at the World’s Most Successful Companies

Verify Our Quality with Customers in Your Area

Our Production Facilities

NUMBER OF COUNTRIES SERVED

40

MANUFACTURING FACILITIES IN THE CHINA

4

UNIQUE PRODUCT DEVELOPERS SERVED

300+

What Sets Us Apart

We offer cutting-edge solutions to solve your toughest challenges with the latest technology.

We carefully check every part to make sure it meets high standards, with almost zero defects.

We handle both small and large orders while ensuring stable performance and scalability.

Saving money through our advanced tech and efficient methods to offer low prices without losing quality.

Our team of 100+ experts in CNC machining and molding can handle complex tasks others can't.

Our quick processes help get your products to market faster, giving you a competitive edge.

Most Popular Questions

Yes, you are welcome to visit our factory for an on-site audit to verify our quality and production capabilities. We can also assist in arranging factory visits or provide detailed information about our factory's certifications and quality control processes, ensuring you feel confident in our quality and capabilities.

Lead times depend on the complexity and volume of your order. For standard lead times typically range from 7-15 days. For complex projects, we will provide an estimated timeline during the quotation process.

Our MOQ varies depending on the complexity of the part and the material used. For most CNC machining and injection molding projects, we can handle orders starting from a few pieces to large-scale production runs.

We implement strict quality control measures, including 100% inspection of critical dimensions, material testing, and in-process checks. We also offer certifications like ISO 9001 for our manufacturing processes.

Our pricing is based on the complexity of the design, the materials required, and the production volume. We provide custom quotes after reviewing your specifications to ensure competitive pricing without compromising quality.

Yes, we offer engineering support during the design phase. Our team can provide design feedback, material recommendations, and manufacturability assessments to optimize your product.

Absolutely! We specialize in OEM/ODM services and can manufacture parts based on your exact specifications, whether it’s from drawings, CAD files, or prototypes.

We can process almost any type of metal or plastic, with no material restrictions. Our range of metals includes aluminum, stainless steel, titanium, copper, brass, alloy steel, magnesium, Inconel, and more. We also work with various plastics such as nylon, acrylic, Delrin, ABS, PEEK, PTFE, PVC, and others.

Yes, we have the capacity to handle both small and large-scale production runs. Our state-of-the-art facilities and skilled workforce can efficiently produce high volumes without compromising quality.

We have over 20 years of experience producing high-precision parts for industries like aerospace, automotive, and medical devices. Our advanced CNC machining and molding capabilities ensure tight tolerances and reliable quality.

Yes, we offer sample production to ensure that the parts meet your exact specifications. Samples will be delivered for approval before full-scale manufacturing begins.

We accept wire transfer (T/T), PayPal. Payment terms are discussed during contract negotiations.

Yes, We can ship parts to every country around the world and have established strong partnerships with trusted logistics companies like FedEx and DHL to ensure timely and secure delivery.

We provide full after-sales support, including assistance with part issues, reorders, or adjustments to specifications. Our customer service team is always available to resolve any concerns.